In today’s era of connectivity and IoT, consumer standards have been raised. Knowing the location of assets and personnel in various environments has transitioned from a convenience to a necessity, especially on the enterprise level. With access to location data, radical improvements can be made to business operations, from optimizing schedules and machine usage (saving time and money), to creating more reliable safety measures in hazardous work environments (reducing damages and even saving lives). While these benefits have been realized, the current Position Intelligence technologies still leave consumers wanting for more. The asset tracking industry as we know it is quite polarized, with most solutions best suited for either indoor or outdoor environments, and none spanning large open spaces without irreconcilable power and connectivity trade-offs.

GNSS is perhaps the most well known tracking method by name. Found on most smart devices à la mapping and direction apps, GNSS is a satellite-based tracking system which operates at long range. While it is capable of providing high-accuracy positioning, it can struggle to perform in obstructed outdoor environments. High walls or surrounding buildings commonly found on many industrial campuses can cause what is known as “canyoning” which can compromise the location accuracy of assets or personnel. GNSS is also extremely power hungry which poses a significant challenge for large-scale deployments. Some supply chain and logistics use cases can have upwards of 5-10k+ assets. Now think about how quickly your phone battery dies when using a navigation app and do the math! Frequent battery replacements or required charging would not only be a logistical nightmare, but could also come with steep operating costs.

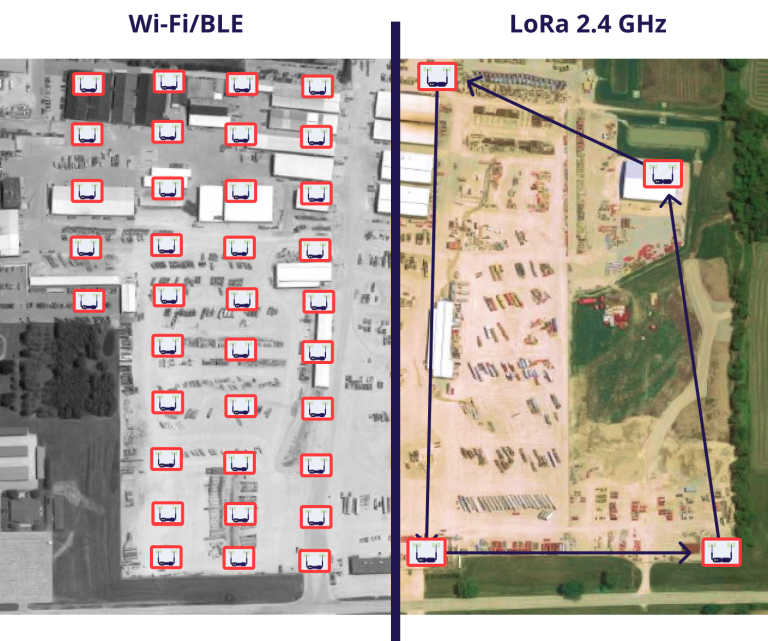

On the other end of the spectrum, Wi-Fi® and BLE tracking solutions operate at short range. Though deployable across many environments, these solutions require dense network infrastructure for accurate positioning. With devices needed approximately every 30-50 metres, these solutions are not sustainable for wide-area use cases such as tracking shipping yards or oil/gas refineries. Considering many outdoor campuses can span 5+ square kilometres, the required devices would quickly add up, resulting in significant cost increase.

With GNSS, Wi-Fi®, and BLE being the main asset tracking technologies on the market today, a gap remains for a solution which can operate at long range with both little infrastructure and low power consumption. While some have tried bundling these into one tracking solution to cater to environmental needs, customers are still left with the headaches due to high costs from poor battery life and the hassle of combining multiple technologies.

danalto, however, has bridged this gap with a distributed software for precision positioning of IoT devices on the industrial and enterprise level. Rather than GNSS, Wi-Fi, or BLE, danalto’s Fine-to-Long Range solution, FiLo®, utilizes LoRa® @ 2.4 GHz, which encompasses the best features of the three in a single technology stack. With LoRa® @ 2.4 GHz, danalto FiLo® can achieve sub-5 meter accuracies at long range and is able to do so with 5x less power and 10x less infrastructure requirements than other tracking solutions. danalto FiLo® also includes an in-built data-backhaul network and solver for seamless data transmission, as well as Cardinal™, danalto’s user-friendly front-end platform. With abilities to create custom tracking “zones” and scheduled position-fix frequencies, danalto’s Cardinal™ + FiLo® solution simplifies asset tracking for open spaces every step of the way.

So, what does this really look like in action? Using a car manufacturer as an example, employees struggle to locate specific vehicles parked within a large 1 km x 2 km inventory lot – especially when the surrounding cars all look the same! Due to the project volume, deploying numerous anchors or up-keeping the frequent battery replacements of power hungry tags would be logistically and financially impractical. With danalto’s LoRa® @ 2.4 GHz tracking solution, this manufacturer can stick to their budget, achieving site coverage with just 4-6 Positioning Anchors and reducing energy costs with ultra low-powered tags. With this system deployed, the site manager may also utilize the front end dashboard to break the lot into bite-sized pieces. By creating their own zones within the lot, the site manager could organize the lot by car model or inspection status, optimizing search-and-find efforts and general business operations.